Structure of various components of electro-hydraulic servo cnc press brake bending machine

An electro-hydraulic servo cnc press brake bending machine is a machine that presses workpieces into different shapes and bends thin plates as needed. It is an important equipment for workpiece bending in the sheet metal industry. Do you know the structure of the various components of the electro-hydraulic servo cnc press brake bending machine? Today, I will share with you:

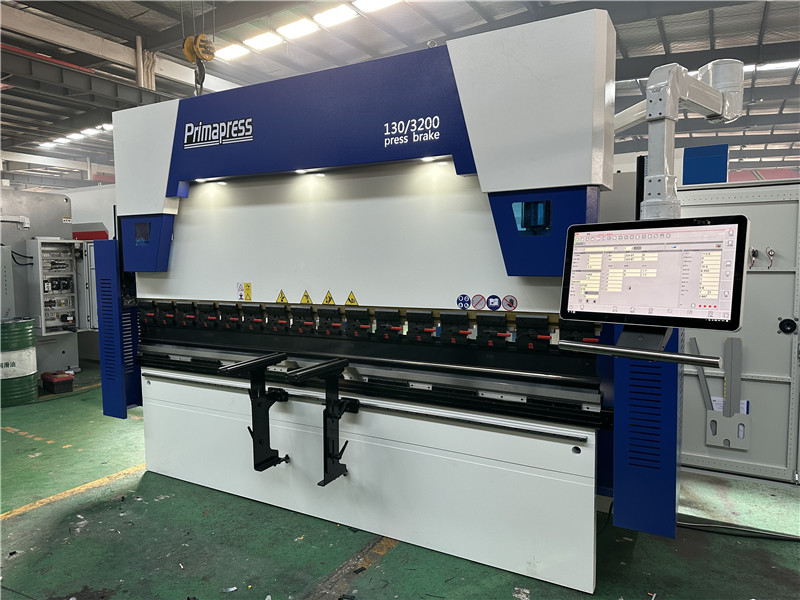

Electrohydraulic servo cnc press brake bending machine

- Oil cylinder (Y1 Y2): fixed on the left and right sides of the cnc press brake bending machine, driving the slider to perform up and down reciprocating motion;

- Sliding block: drives the upper mold to move back and forth in a straight line relative to the lower mold to achieve bending of the sheet metal, forming a certain bending angle (or arc);

- Quick clamp: Adjust the mold to ensure even force, prevent damage to the slider, and ensure stable machining accuracy of the workpiece;

- Front bracket: used to support the sheet to be bent, adjustable up and down;

- CNC system: controls the cnc press brake bending machine to execute machining programs. It can store various different programs, equipped with interface circuits and servo drive devices;

- Mold: A mold used for sheet metal stamping and separation, generally divided into upper mold and lower mold. Under the pressure of the cnc press brake bending machine, the workpiece is made into a production tool with a specified shape and size;

- Mechanical compensation: to ensure the accuracy of the processed parts and compensate for the deflection deformation of the slider;

- Foot pedal: Control the gear finger to move left and right, turn on and off the machine, integrate machine tool control, etc;

- Servo motor: Select servo motor with high precision, fast speed, and stable operation;

- Back blocking material: The back blocking material can be flexibly folded into small pieces, and the front blocking material has a very good forming effect. Dual drive front and rear material blocking, more accurate positioning of rear material blocking, and good forming size of front material blocking;

Above, I have shared with you the characteristics of the 10 major component structures of the electro-hydraulic servo cnc press brake bending machine, hoping that everyone has a deeper understanding of the electro-hydraulic servo cnc press brake bending machine.