Deep Throat Metal Punch is also called Deep Neck Metal Punch, Deep Throat Metal Punch. It refers to the distance from the center of the shank hole of the punch to the back wall panel.

There are 300mm, 500mm, 800mm. There is also a throat depth of 1250mm. This should be customized according to actual production needs. The deep-throat metal punch is a kind of metal punch, which is generally used in sheet metal punching, such as the shutters opened in the middle of large electrical boxes and electrical cabinets, the cat eyes opened in the middle of the

anti-theft door, because the distance between the material hole and the edge of the board is usually more than 300mm Or more, and the throat depth of ordinary metal punches is only about 180-230. After the sheet is put into the metal punch, the wall plate blocks the sheet, and the distance between the hole and the edge of the plate cannot be achieved by 300 or 500, which requires the use of Deep throat metal punch to achieve.

Deep throat metal punch model JB21S series, the throat depth refers to the distance from the center of the shank hole of the punch to the back wall panel, and there are 300mm, 500mm,

800mm. There are also throat depths of 1250mm, which depends on actual production. Need to be customized. The throat depth of ordinary metal punches is only about 180-230.

After the sheet is put into the metal punch, the wall plate blocks the sheet, and the distance between the material hole and the edge of the board cannot be achieved by 300 or 500.

This requires a deep-throat metal punch. accomplish.

80 tons deep throat metal punch throat depth 1250mm!

Shallow throats are ordinary mechanical metal punches, such as open fixed table metal punches, open tiltable metal punches, etc. From the appearance, a large piece recessed behind the metal punch table is a deep throat metal punch, which is cost-effective. It is better than tiltable metal punches. We can also see the advantages in terms of speed, control and accuracy. Generally, the speed of deep-throat metal punches is 200-1000 times. Ordinary metal punches have manual and foot pedals, while deep-throat metal punches It is CNC, fully automatic feeding, saving time and cost, not to mention the accuracy. Deep-throat metal punches can also press everything, but it mainly depends on the mold. Reasonable mold structure, precise and good heat treatment, mold installation accuracy and use determine the service life. Before mold installation and use, the metal punch should be strictly inspected and removed. Check whether the guide sleeve of the mold and the mold are well lubricated; check the metal punch turntable and mold installation base regularly to ensure the coaxial accuracy of the upper and lower turntables; follow the mold installation procedure

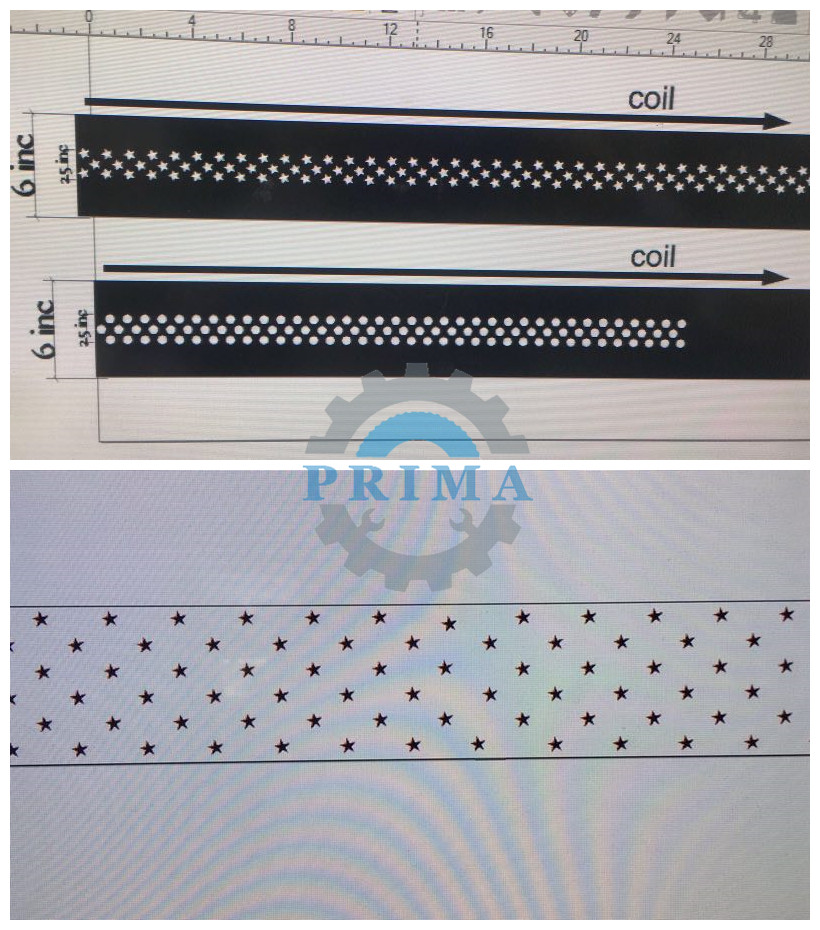

Application areas: In addition, some manufacturers add CNC systems to improve production efficiency, and to maximize the effectiveness of CNC, they also need to use deep-throat metal punches. Deep-throat metal punches are widely used in silencers for airplanes, luxury buses and high-speed EMUs. And the radiating plate punching, the shutter punching of the electrical box and the electrical cabinet, the anti-theft door key hole and the peephole punching, the fresh-keeping cabinet cooling hole, etc.