Answers to the common problems of iron plate cnc fiber laser cutting machine

Here, you can find solutions to the common problems of metal plate fiber laser cutting machine and laser cutting process.

What is the working principle of laser cutting machine?

Laser cutting is used to illuminate the workpiece with high power density laser beam,to make the workpiece rapidly melt,

vaporize, abate or reach the point of ignition, at the same time, the molten material is blown out by the high-speed airflow

which is coaxial with the beam to the workpiece, through moving light spot position by the CNC mechanical system to cut workpiece.

Is laser cutter operating dangerous?

fiber Laser cutting is an environmental friendly cutting method and has no harm to our body.Compared with ion cutting and oxygen cutting,

fiber laser cutting produces less dust, light and noise.While if you don’t follow the proper operation method, it can also cause personal injury or machine damage.

1.Beware of flammable materials when using machine.Some materials could not be cut by laser cutting machine, including foaming core material,

all the PVC materials, high reflective material and so on.

2.In the machine working process, the operator is forbidden to leave to avoid unnecessary losses.

3.Don’t stare at the laser cutting processing. It is forbidden to observe the laser beams through binoculars, microscope or magnifying glasses.

4.Do not put explosive or flammable materials in the laser processing area.

Which factors could effect the precision of laser cutting machine?

There are many factors can affect the laser cutting accuracy, some factors are caused by the equipment itself, such as mechanical system precision,

table vibration level, laser beam quality, auxiliary gas, nozzle etc, some factors are inherent material factors, such as the physical and chemical

properties of materials , the reflectivity of the material, etc.Other factors like parameters can be adjusted based on the specific processing

object and the user’s quality requirements, such as output power, focal position, cutting speed, auxiliary gas etc.

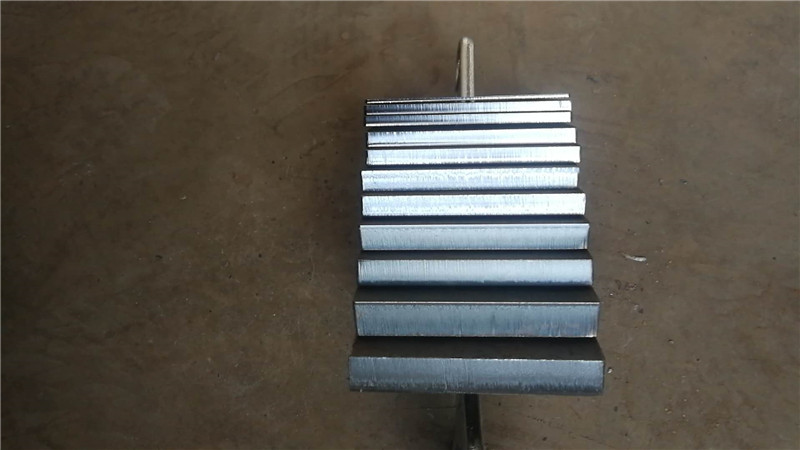

How to find the focal position of fiber laser cutting machine ?

Laser power density has a great influence on the cutting speed, so the selection of the focal position is particularly important.

The spot size of the laser beam is proportional to the length of the lens. There are three simple ways to find the cutting focus position in the industrial files:

1.Pulse method: Let laser beam print on a plastic sheet,moving the laser head from top to bottom,checking all holes and the smallest diameter is the focus.

2.Slant plate method: Using a slant plate under the vertical axis, moving it horizontally and looking for the laser beam at the minimum focus.

3.Blue Spark: Remove the nozzle, blow the air, pulse on stainless steel plate, move the laser head from top to bottom, until find the blue spark as the focus.

At present, many manufacturers’ machines have automatic focus.Automatic focus can significantly improve the laser cutting machine’ efficiency,

piercing time on thick plate is significantly reduced; The machine can adjust automatically to find the focus position based on different materials and thickness.

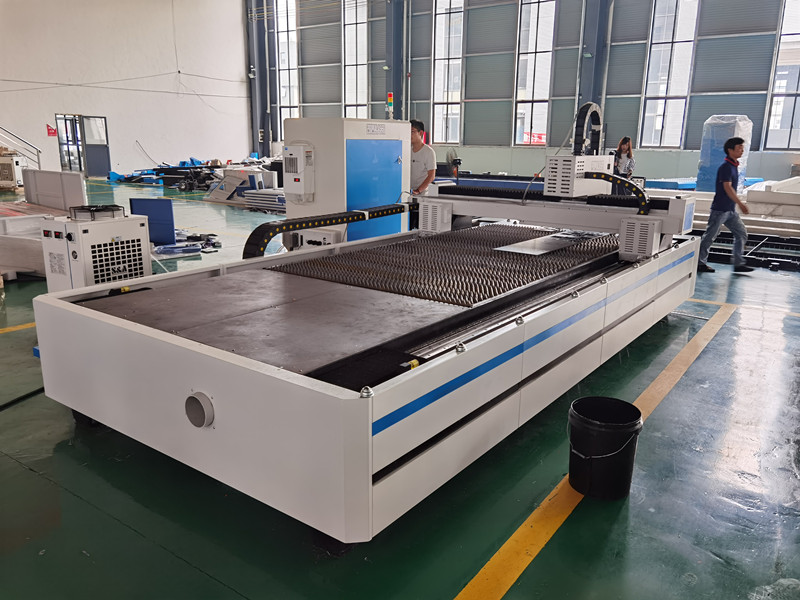

How many types of laser machine have? What’s the difference between them?

Currently, lasers for laser processing manufacturing mainly include CO2 laser, YAG laser, fiber laser,etc. Among them, high-power

CO2 laser and YAG laser have more applications in the confidentiality processing. Fiber lasers with fiber-optic matrix have

obvious advantages in reducing the threshold, the range of the oscillation wavelength and the tunability of the wavelength,

it has become the emerging technology in the field of the laser industry.

What’s the cutting thickness of fiber laser cutting machine?

At present, cutting thickness of laser cutting machine is less than 25mm, compared with other cutting methods, laser cutting machine

has a clear advantage in cutting material less than 20mm with high accuracy requirement.

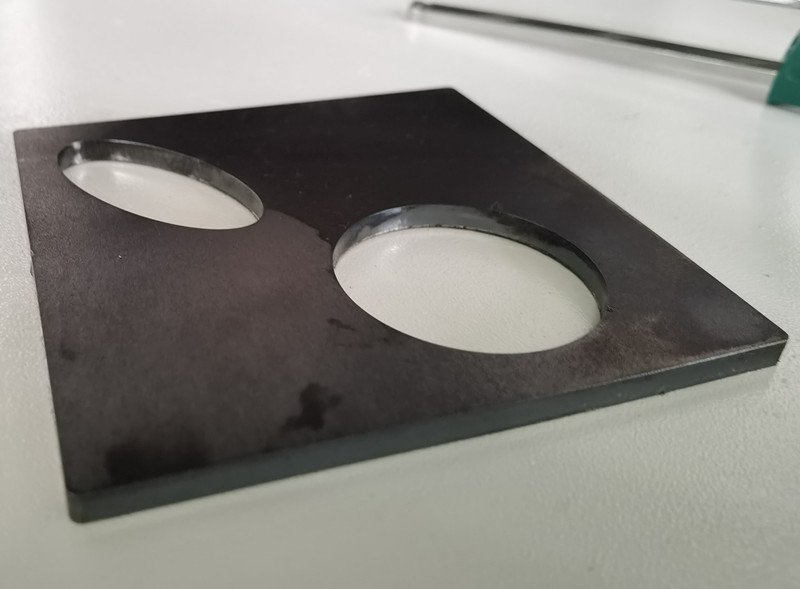

What’s the application range of laser cutting machines?

Laser cutting machine has high speed, narrow width, good cutting quality, small heat affecting area and good flexible processing,

so it is widely used in automobile manufacturing, kitchen industry, sheet metal processing, advertising industry,

machinery manufacturing, cabinet processing, elevator manufacturing, fitness equipment and other industries.